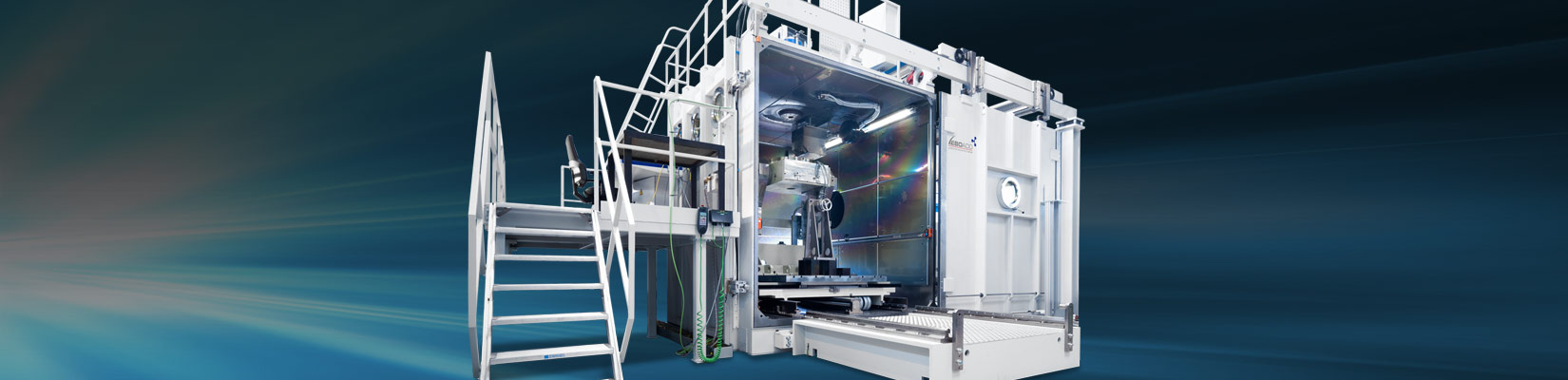

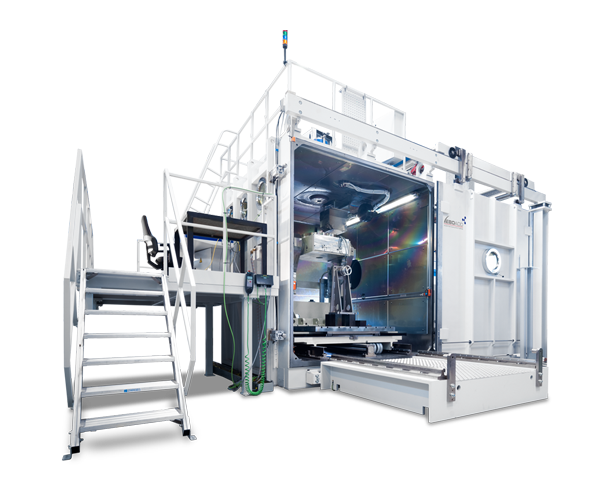

PRECISION IN DETAIL

AND A WIDE RANGE OF OPTIONS

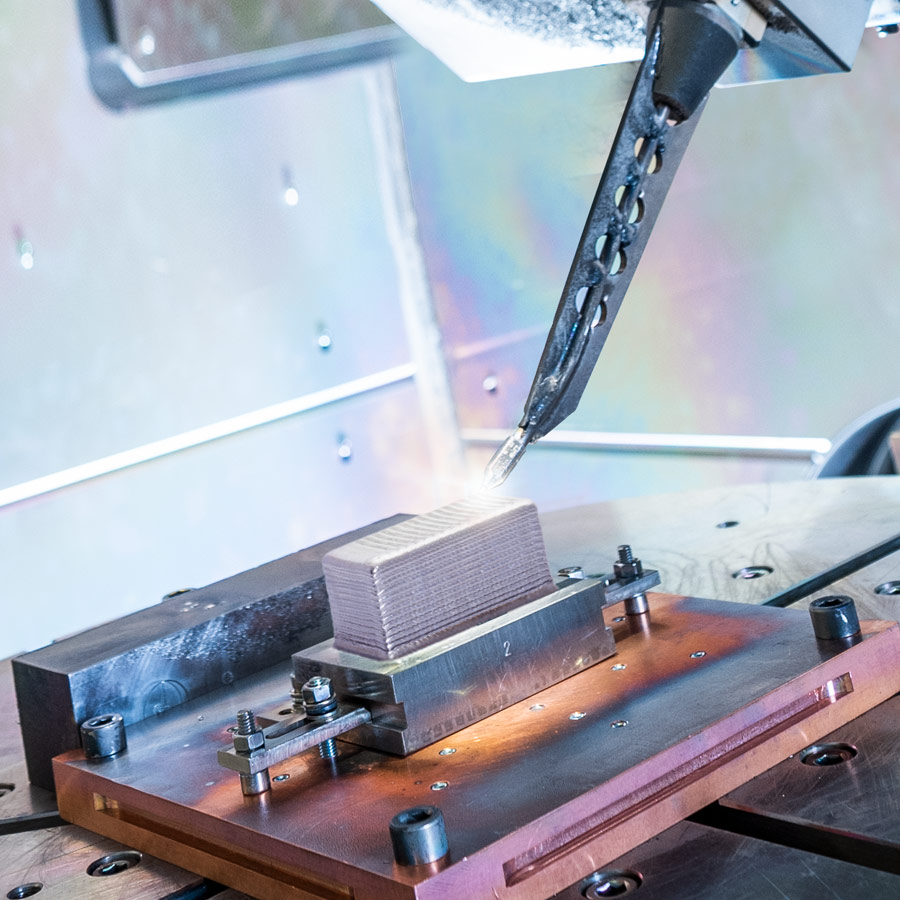

Additive manufacturing with the EBOADD process uses an electron beam as an efficient source of energy. It is generated in the electron beam chamber machine from Steigerwald with a powerful generator of the EBOGEN series. The movable EB generators enable power flux densities of more than 107 W/cm2.

The electron beam melts the initial material during processing which makes it possible to continuously build up the workpiece.

The welding process takes place in a vacuum. Therefore, among other advantages, very high build-up speeds can be realized.